AUTOMATION AND CONTROLS

From plant floor to executive suite to the cloud.

Let us be your guide.

AUTOMATION AND CONTROLS

From plant floor to executive suite to the cloud.

Let us be your guide.

* Certified as a Women Owned Business Enterprise (WBE) by City of Albany, NY *

Your process. Your product. Our programs.

North Point Technology, LLC is an industrial automation and control systems integration firm, which provides engineering consulting, design, programming, training, maintenance and support services to industrial and municipal clients around the globe. We are a Woman Owned Business Enterprise (WBE) and Small Business Enterprise (SBE).

Our team of highly specialized engineers is experienced in a wide variety of industries and certified in key software products and tools, allowing us to apply the best programming solutions to optimize systems and integrate equipment. We work with large and small clients around the world and close to home, lowering the cost of doing business while delivering superior results.

North Point Technology, LLC is classified as a Small Business and a Woman Owned Business Enterprise (WBE) and holds a certification for same from the City of Albany. We have recently submitted our application to New York State for WBE certification.

Our systems and services:

Optimize and enhance processes and control

Provide regulatory and operations reporting

Minimize power and chemical consumption

Allow remote access and monitoring

Lower operating and training costs

Enhance operator usability

Reduce system downtime

Save time and money

What We Offer

We design, program and commission:

PLC and DCS Systems

SCADA and HMI Systems

Historian and Reporting Systems

Ethernet and Fieldbus Networks

Telemetry and secure networking

Drives and Motion Controllers

Machine Control and Vision Systems

Instrumentation and Analysis

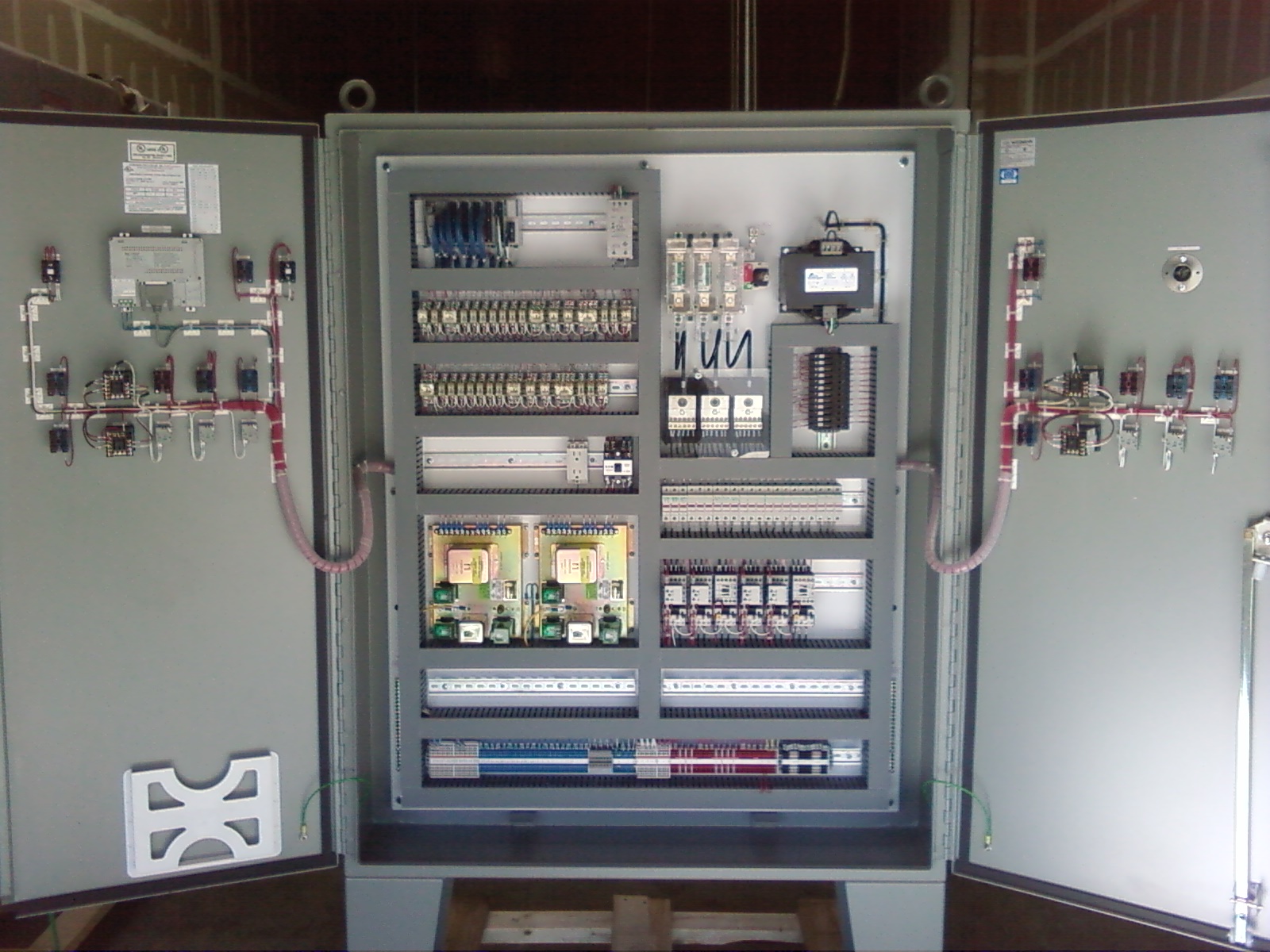

Control Panels and Hardware

IIoT and Cloud Computing

Specialized mobile app development

What Our Clients Say:

Are you looking for information on our monthly Computer Systems Health Monitoring service? Our experienced engineers can remotely update, test, and back up your SCADA and other control system PCs. Click here to go to that web page!

Traditional Controls

Plan for success, design for reliability in line with upfront and ongoing costs, build for safety and security, program for function and usability. Let North Point map your route. We help build the trails and draw the trail maps.

Traditional Controls

Plan for success, design for reliability in line with upfront and ongoing costs, build for safety and security, program for function and usability. Let North Point map your route. We help build the trails and draw the trail maps.

MACHINE AND PLANT LEVEL AUTOMATION

PLC systems with hardware based HMIs are the workhorses of industrial automation. They deliver safe, reliable process and machine automation for factories and shops around the world. SCADA and historian systems concentrate data and operational functions in control rooms and allow view from offices and mobile PCs. DCS systems combine both and span entire integrated processing plants. Our business grew from this base and it remains the core of our service offering.

We have created products designed to improve the usability of client systems which also reduce programming time, errors and commissioning time during project development.

- The ActiveX Prompt Control is installed in SCADA packages for state-based processes- those with multiple steps or statuses. The control displays complex plain-language readable messages including live embedded data. So if your process is stopped for a timed event, or waiting for a level to fill, your operators can see why it is stopped and the live process on the timing or filling operations. No SCADA system provides this type of function natively.

- APC or Automation Project Configurator is an advanced modeling system that allows users to create complete, interlinked structured representation of a control system, including library-based objects, relationships between objects, IO assignment and more. From the complete model, the user can generate complete importable PLC code, SCADA database tags including alarming and history, reports suitable for submittal, and more. By automating code generation, APC reduces programming time, eliminates errors, improves communication with stakeholders during development, and speeds up commissioning by allowing personnel to focus on testing higher-level custom functions, being assured that code generated with APC was pre-tested and error-free.

North Point reviews your specifications, interviews stakeholders and examines your systems to understand your needs. Through research and analysis, we determine where you are and where you could be. Our analysis will indicate the most cost effective ways to improve your system. Our team has probably handled similar requirements in the past and so can start out quickly and efficiently. Our process experience includes:

- Advanced potable water filtration and treatment, including membrane, reverse osmosis (RO) and UV sterilization

- Traditional potable water systems, including mixed media filtration, flocculators, clarifiers, sedimentation, and sludge handling

- Water distribution including pump stations, telemetrics, multi-pressure plane high service pump control

- Advanced wastewater treatment including secondary filtration with membranes for re-use, and MBR (membrane bio-reactor)

- Chemical batching systems including ratio-controlled crystallization reactors

- Steam and power plant boiler control

- Experimental process control systems- algae separation, gas to liquid, concentration filtration, etc

- Oil and gas industry services including waste disposal injection wells

- Ammonia refrigeration systems

- Conveyor control and material handling systems

- Automated testing for machinery subsystems and metrology (measurement) for discrete parts quality control

- District cooling including lake source cooling

- Glass and ceramic manufacturing and product handling

- and many more! Ask if we have the critical experience for your project.

Beyond The Plant Floor

The Industrial Internet of Things (IIoT), cloud computing, cloud services, data analytics, mobile software. Let us use our experience to help sort out the what, why, and how of this new confluence of IT technology and traditional controls. We have crossed that bridge before and can lead you across too.

Beyond The Plant Floor

The Industrial Internet of Things (IIoT), cloud computing, cloud services, data analytics, mobile software. Let us use our experience to help sort out the what, why, and how of this new confluence of IT technology and traditional controls. We have crossed that bridge before and can lead you across too.

cloud computing

SCADA and Database Hosting

Leverage the quality of service, reliability, disaster and fault tolerance and cost savings by moving assets to the Cloud.

Split your SCADA between local and cloud, publish KPIs on the web, prepare and deliver reports to anyone, or host your entire SCADA, database or business process application safely and securely in the Cloud.

APP DEVELOPMENT

Put data where it is used

Your users access the digital world via their mobile devices more than they do any other way.

Why not your business or SCADA too? We leverage existing technology and write applications for mobile platforms to bring the interface to where it is needed most. IOS (Swift), Firebase, MQTT, Amazon and Google cloud platform services are all available in our toolbox.

iot and iiot

Pub/Sub with MQTT and more

Technologies that make up the "Internet of Things" and the "Industrial Internet of Things" are rapidly making it faster and cheaper to get data from and deliver data to individual devices that were not traditionally networked. Data from many, many disparate devices can be combined and analyzed to provide insights and optimizations never before possible.

It is predicted that 50 billion sensor-equipped systems will by connected to the internet by 2020. We are ready to partner with you to survive and thrive during this radical shift in industry.

custom business applications

Database-backed custom business process automation

North Point Technology has extended our experience in high end SCADA systems to a new level by using elements of existing infrastructure and new technology to create fully integrated business process applications. Our business process systems use secure relational database systems hosted locally or in the cloud on SSL-encrypted services. Our team will analyze your existing processes and work with you to plan out new or upgraded components to achieve your project goals, such as reductions in paperwork, manual labor, turnaround time, and errors, or increased throughput.

Once the revised process is charted, we develop user interface screens, reports, email and SMS communications, set-time data processing, and add hardware required, such as barcode readers or label printers.

Real-world, operating business processes using our technology include for example raw material receiving, lab testing, lot tracking, lot blending calculations, chemical batch confirmation of materials and lot-to-product tracking and reporting for an international speciality chemical manufacturer. This process includes multiple departments, integrates with a separate accounting system, and provides users with many branches for exception handling in accordance with the real-life process. It also includes data archive and reporting to allow products to be traced back to specific raw material lots and manufacturers used, at production time or in the future. Email notification of events like QC tests passed or failed reduces or eliminates paperwork and improves efficiency. The business process application is also available on mobile devices.

Overview of raw material business process system. Each button reaches a screen allowing operators to perform the relevant functions, all linked to the same relational database.