For my husband Bob and I, life in Broome County is defined by the family and business - North Point Technology, LLC - that we’ve built here together.

I grew up in Endwell and went to Union-Endicott High School and Binghamton University before transferring to Cornell University, where I earned my Bachelor’s Degree in Industrial and Labor Relations.

After college I held a variety of positions in business administration and executive management– including work in human resources, recruiting, compliance, training and development, and operations for locally-based businesses, such as United Health Services, Singer-Link Flight Simulation, and Anitec, a division of International Paper Company, which is where Bob and I met.

While I’m a native of the area, Bob is originally from Towanda, Pennsylvania. He attended school in Philadelphia and received his BS in Electrical Engineering from Temple University before moving to Broome County in 1990 for a position with Anitec/International Paper Company.

After Anitec was bought and sold by Kodak, Bob worked for engineering consulting firms in Corning and Endicott.

It was while managing an engineering firm’s Endicott branch office that Bob realized he was doing most tasks typical of business owners such as conducting sales, initiating marketing efforts, managing employees and projects, and winning and building relationships with new customers.

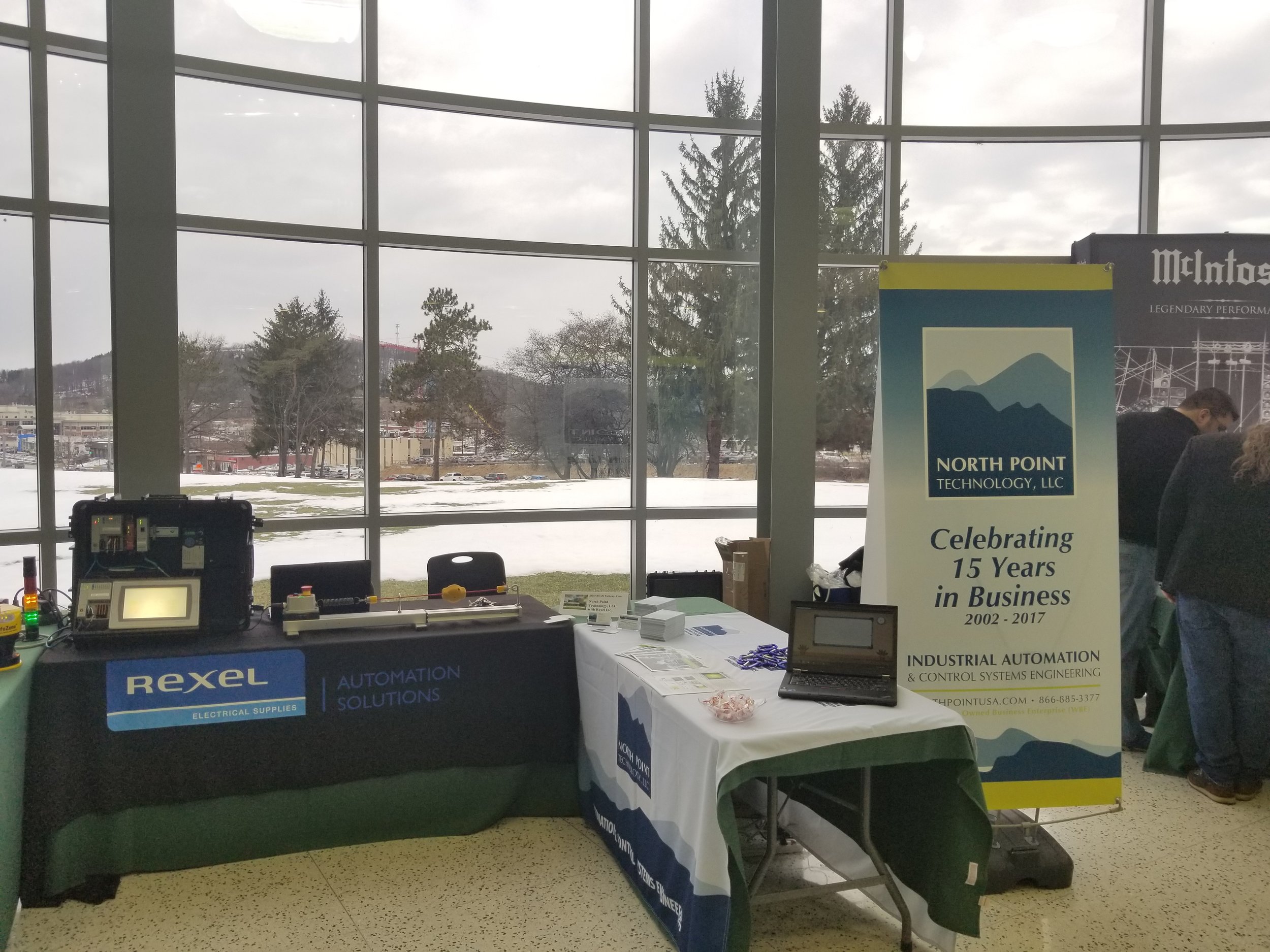

This experience, combined with his innovative nature - he’s always looking for more efficient and better ways to do something, even if it means creating technical and business software products for his own firm - eventually pushed Bob to go off on his own to start North Point Technology in 2002, on a borrowed desk in our basement.

I was working for Blue Cross & Blue Shield of Western NY around this time. I eventually became their Corporate HR Director overseeing functions in Buffalo, Albany and Binghamton and found myself traveling to the Buffalo corporate office three days a week, while Bob worked from home and cared for our daughter - the first of three children.

At this point, we realized we wanted to really build and raise our family here, so I took a position locally and helped Bob build the infrastructure and internal processes of North Point, as well as harnessed my technical recruiting background to assist in hiring the company’s first employee, another automation engineer, in 2003.

I formally joined North Point in 2007, and in 2008 I decided to move our home-based business to our first formal office space in the former Azon building in Johnson City - we had all been working remotely from home up until that time. We later relocated to offices in the Columbia Ridge Office Park in JC, where we’ve been since 2010.

Building North Point Technology has been a rewarding challenge. We’ve encountered obstacles every business owner faces and also challenges specific to a company like ours – a hybrid of several different engineering disciplines.

North Point Technology, LLC is an industrial automation and control systems engineering firm that designs, builds and programs specialized computer software and systems that run factories, warehouses, industrial and municipal water plants all over the globe.

We do everything from traditional automation and control systems - PLC’s, HMI’s and SCADA- that run factories or water plants, to pure automation consulting for safety, security and reliability services, to working with companies to develop their internal automation strategies and platforms.

We’ve provided these services for countless clients nationwide as well as in Canada, the Caribbean, Europe, China, South America, Australia – anywhere our clients send us.

Our life and work in Broome has enabled Bob to travel all over the world on projects, but there’s something very special about getting to use our skills and expertise to serve other local businesses right here in our home state.

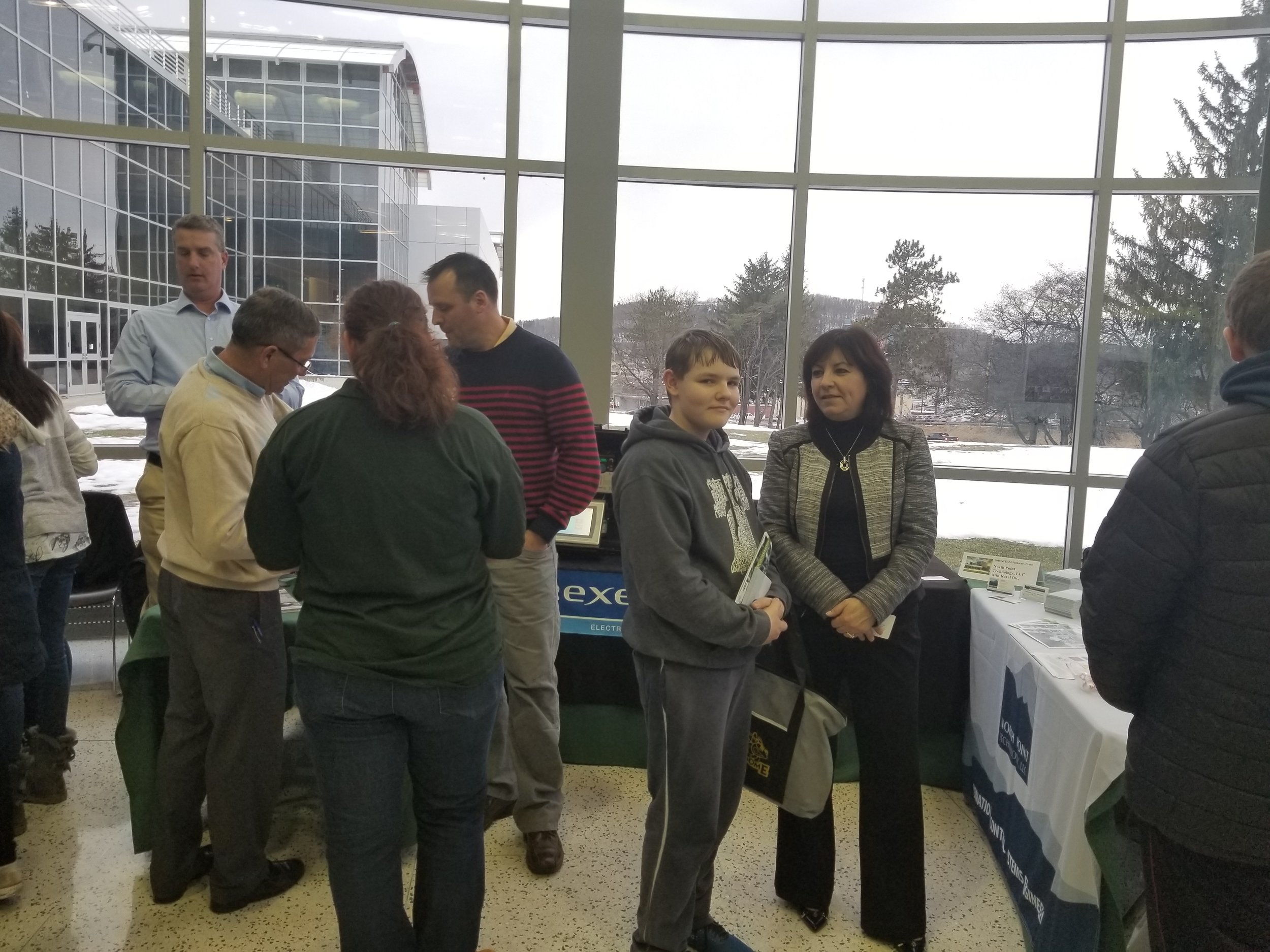

Now, we’re looking at how we can work with other local companies and provide them with automation or control systems services and solutions they didn’t even know were being carried out in Broome County.

We’ve always been committed to Broome County, recruiting employees from larger cities by showcasing all the Southern Tier has to offer them and their families.

Choosing Broome has also enabled me to give back. I’ve served on the ACHIEVE Board of Directors, the Broome County United Way Allocation Panels, and currently serve on the Board of Directors for United Methodist Homes, as well as the Endicott Proud Committee, which is dedicated to revitalizing Endicott.

Bob and I often ask ourselves, “What are our goals?” And one of the most important is that we want to be here. We like it here. It’s a beautiful region of the country and we want to raise our family here, as well as support this area.

There’s this family feeling here. The people are close and friendly - and willing to reach out their hand to help you. Many local business and community leaders are very accessible and are willing to meet and partner with you to help you in business. That, in my opinion, is our strength in this community, and will help us revive this “Valley of Opportunity.”

You really can have the best of both worlds in Broome County, particularly in your business.

You can work here and travel around the world. You can go to Europe or Asia or across the U.S., but then you can just come back and have a comfortable place to call home, surrounded by a supportive family and a caring, helpful community.

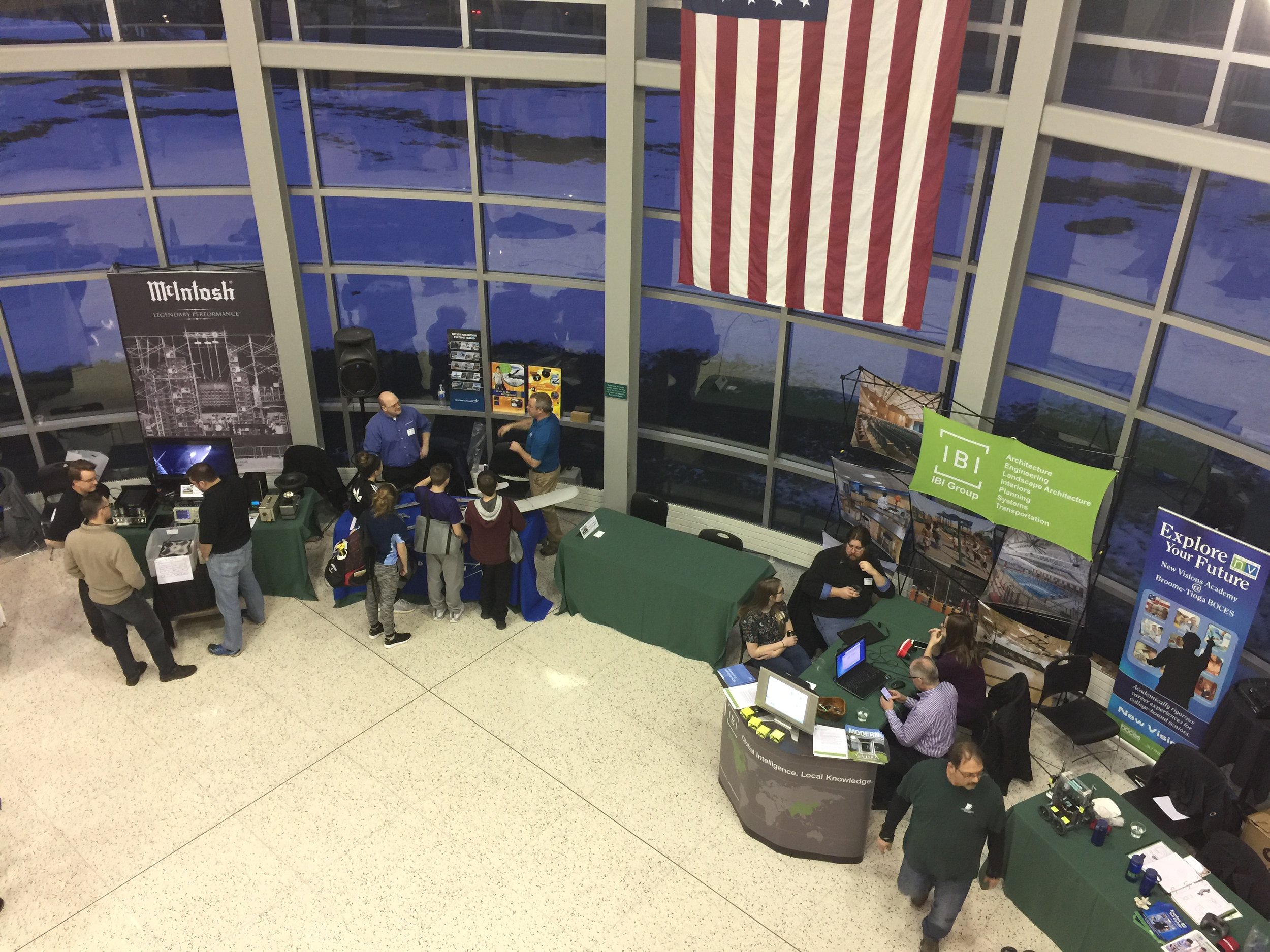

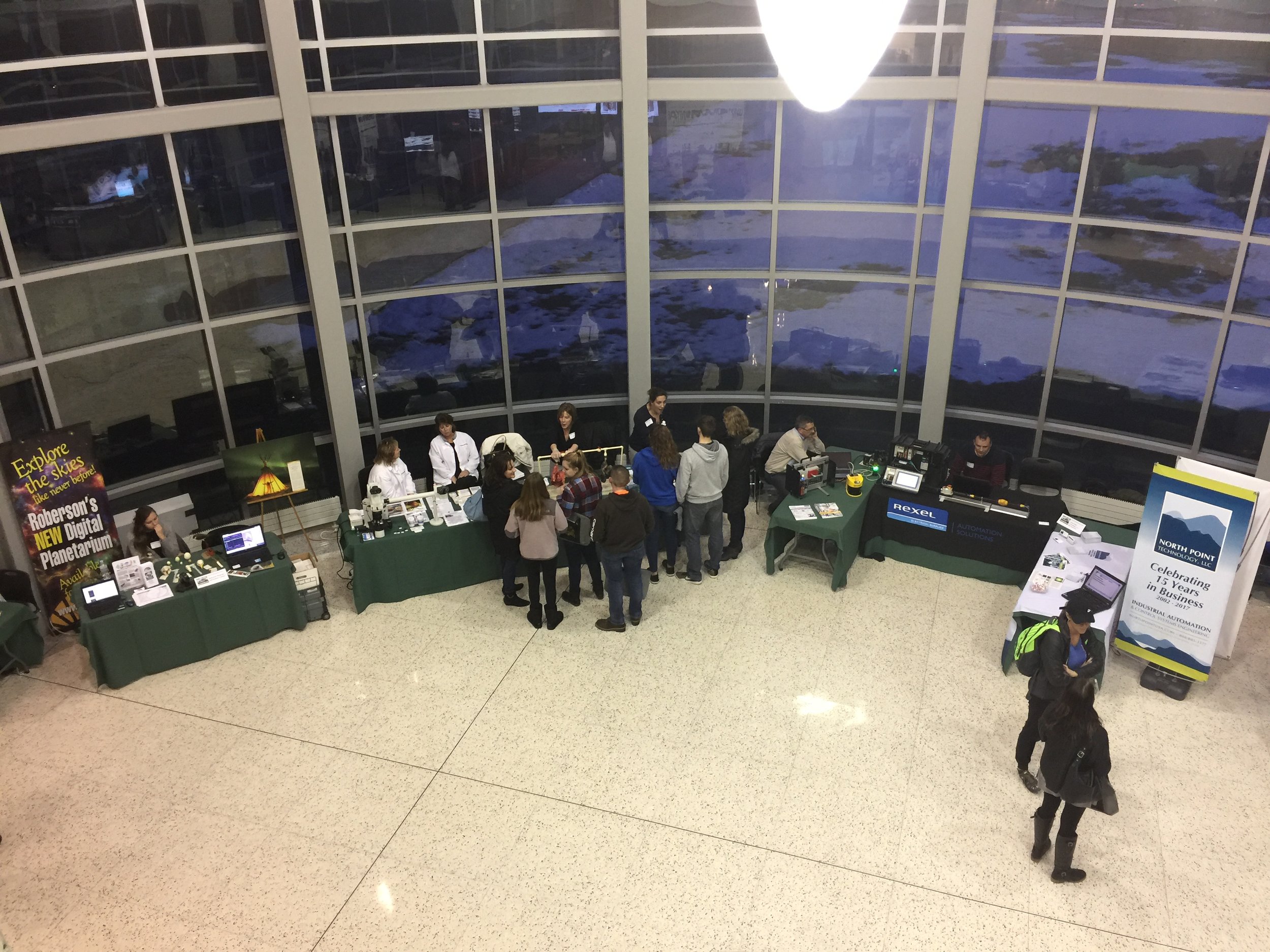

North Point Technology, LLC is part of why #Broomeisgood. Learn more about them at http://www.northpointusa.com/#new-home.

Lisa and Bob’s story is part of the Broome County...a good life™ program. This program was created by The Agency Broome County IDA/LDC to promote the ideal work/life opportunities offered in Broome County. To learn more, visit www.theagency-ny.com. To share your story, become a Good Life Investor, or to learn why others choose Broome, visit www.broomeisgood.com#Broomeisgood.

Members of the editorial and news staff of the USA Today Network were not involved in the creation of this content.